ACHIEVE

Find out more about POP,

OUR PERFORMANCE OPTIMISATION PROGRAM

PHASE 1

Identification

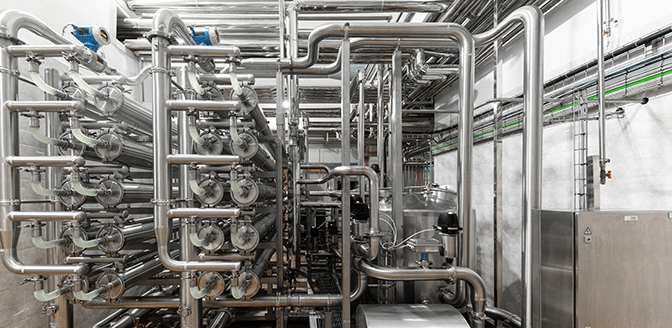

Our experts carry out a membrane audit to assess the type and rate of fouling in your filtration units. A precise operation carried out with non-aggressive technical solutions for your equipment.

01

Identification of the fouling

Organic or inorganic fouling or presence of biofilm contamination

02

Evaluation of the impact of the solution

Water solubility and recovery rates of water flows

03

Observation of different values

Measurement of ATP and turbidity of the solution on the retentate side. Pressure and flow rate on the permeate side.

TOGETHER LET’S FIND

Performance first and foremost, yes, but the right performance! We select or develop for you a product calibrated to your needs.

PHASE 2

Selection and recommendation

Based on the results of the audit, we select from our solutions the most suitable treatment for the type of fouling encountered. High-performance enzyme complexes and a unique protocol for cleaning the filtration membranes developed for your installation. We take into account your procedures, the type of membrane and the fluids filtered.

PHASE 3

Follow-up, monitoring and co-creation

Because we see optimisation as a continuous improvement process, our teams are there to support you on a daily basis.

Thanks to our pilot tests carried out in your factories and our close relations with well-known equipment manufacturers, our innovation division benefits from key information to formulate unprecedented, environmentally friendly solutions.

You benefit exclusively from our latest innovations.

Enzymatic or chemical range enrichment to cover targeted applications and niche segments such as plant-based dairy substitutes, blood plasma, fruit juices, gelatin and beer.